21.5mm Anti-Sun Tinted Toughened Laminated Glass Calculator | Free Radius, Holes, Polishing, Delivery**

£321.75 - £643.50 / per m2 inc VAT

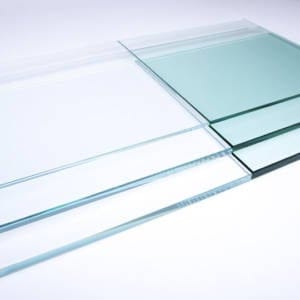

- Buy bespoke cut Anti-Sun Tinted Toughened Laminated Glass Cut to Size | 21.5mm thick

- FREE EDGE POLISHING

- FREE HOLES**

- FREE RADIUS CORNERS

- FREE DELIVERY**

- Opt: Ritec Self Cleaning, Shaping, Sandblasting, Layer Printing, Back Painting

Laminated Glass - Minimum Charge 0.5m2 (per panel)

Toughened / Float Glass - Minimum Charge 0.3m2(per panel)

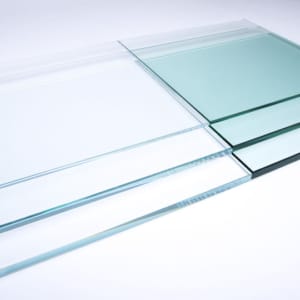

| Glass Thickness: 21.5mm | |

| Glass Type: Clear Anti-Sun Tinted Toughened Laminated |

- Description

- Additional information

- Glass Guide

Description

Buy Glass supplies Pilkington Optifloat™ Tint, 21.5mm Anti-Sun Tinted Toughened Laminated, which is body tinted glass available in a choice of colours; Bronze, Grey, Pilkington Arctic Blue™.

Pilkington Optifloat™ Tint can be used for visual appeal, to reduce glare or where a degree of solar control performance is required. It may be used for exterior and interior applications.

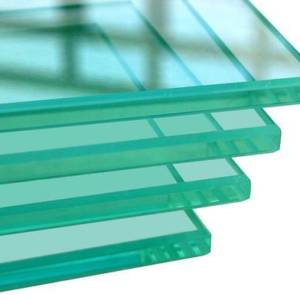

The range of thicknesses available enable glass to be used where superior strength, greater spans, reduced deflection, higher daylight transmission and enhanced noise suppression are required.

Pilkington Optifloat™ Tint can be toughened or laminated or used in Insulating Glass Units.

Buy Glass Toughened glass is 4 to 5 times stronger than annealed glass of the same thickness and is best designed for the most important applications for protection. Nevertheless, close consideration must be given to its use at high level because if it is broken the glass will break into small pieces and will no longer bear a load or act as a barrier. Consequently, not completely framed toughened glass is likely to break off its fixings.

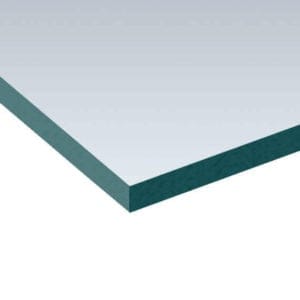

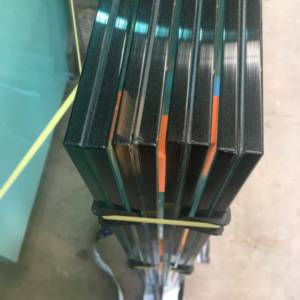

The safe solution is BuyGlass.Co’s 21.5mm Anti-Sun Tinted Toughened Laminated glass which consists of sheets of Low Iron toughened safety glass bonded together with a tough plastic interlayer improving protection and safety as well as preserving pieces of glass in the event of breakage.

What are the uses for Anti-Sun Tinted Toughened Laminated Glass?

- Roof glazing Glass

- Canopy Glass

- Balustrade Glass

- Partitioning Glass

- Floor Glass

- Lifts & Elevator Glass

- Well Cover Glass

- Free standing barrier Glass

- Full height barrier Glass

- Balcony Glass

- Mezzanine safety barrier Glass

You can also combine BuyGlass’ 21.5mm Anti-Sun Tinted Toughened Laminated with BuyGlass Acoustic Inter-layer, BuyGlass Thermal Inter-layer, BuyGlass Color Inter-layer & BuyGlass coating products to add acoustic, solar, thermal insulation and thousands of potential colours.

You, the specifier, are responsible for checking with building control and/or other regulatory bodies to ensure that 21.5mm Anti-Sun Tinted Toughened Laminated and the fitting are suitable for your specific project. We are a supply only company.

Additional information

| Dimensions | 1000 × 1000 × 21.5 mm |

|---|---|

| Glass Type | |

| Glass Thickness | |

| Safety Glass | |

| Min Handling | |

| Max Handling | |

| Unit Price Base Measurement | |

| Unit Price Measurement |

Edge Polishing

BuyGlass.Co pride ourselves on creating a beautiful end product. With edge polishing there are a few things to consider before you purchase & when evaluating the glass you receive.

Depending on the process used, the edge finish can vary slightly between panels. All BuyGlass.Co edge polishing is finished to an exceptional standard and fully QC'd before release.

If you require a uniform finish across all pieces then please contact us after the order is placed.

Otherwise we will process the polishing using whichever process we choose, and although generally this would mean all glass uses the same polishing technique there are certain times when we may use various methods.

Glass Corners

Corners are supplied, as standard, with dubbed corner. If you require unfinished or radius corner please let us know.

Laminated Glass

We use multiple methods for creating laminated glass. CIP, SGP, PVB & EVA are totally different processes which produce very similar results. CIP however, due to the injection process, has a faint area at the perimeter which can be seen upon closer inspection.

** WE GENERALLY USE PVB **

If you would prefer any particular method then you must let us know prior to production or else, at our discretion, we will use any method.