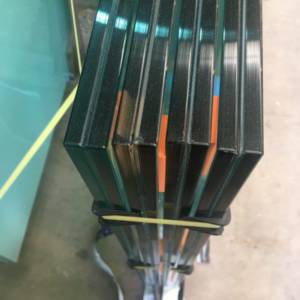

Buy 6.8mm Acoustic Laminate Glass cut to size

£72.00 - £144.00 / per m2

| Glass Thickness: 6.8 |

- Description

- Additional information

- Glass Guide

Description

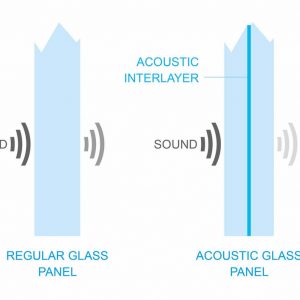

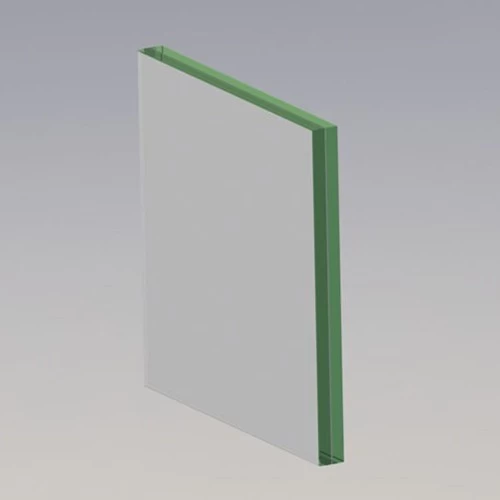

6.8mm acoustic laminate glass is a specialized type of laminated glass designed to provide enhanced sound insulation properties. It consists of two layers of glass bonded together with a specially engineered acoustic interlayer, typically made of a combination of PVB (polyvinyl butyral) and SGP (SentryGlas® Plus).

High Specifications of 6.8mm Acoustic Laminate Glass:

- Sound Insulation: The primary advantage of 6.8mm acoustic laminate glass is its exceptional sound insulation capabilities. The unique acoustic interlayer acts as a sound dampening barrier, effectively reducing the transmission of noise vibrations. This helps to create a quieter and more comfortable indoor environment by minimizing external noise disturbances, such as traffic, construction, or loud machinery.

- Safety: Similar to standard laminated glass, 6.8mm acoustic laminate glass also offers safety benefits. The interlayer holds the glass layers together upon impact or breakage, preventing them from separating and reducing the risk of injury from sharp glass fragments. This enhances the safety of occupants and is particularly important in areas where safety is a priority.

- UV Protection: 6.8mm acoustic laminate glass provides significant protection against harmful ultraviolet (UV) radiation. It blocks a substantial portion of UV rays, minimizing the fading and damage caused to interior furnishings, such as furniture, flooring, and artwork, due to prolonged exposure to sunlight. This UV protection ensures the preservation and longevity of sensitive materials.

- Design Versatility: Acoustic laminate glass can be customized to meet specific design requirements. It can be combined with other glass types, such as tinted glass or low-emissivity (low-E) glass, to further enhance energy efficiency or achieve specific aesthetic effects. This design versatility allows for creative applications in various architectural projects.

- Enhanced Strength: 6.8mm acoustic laminate glass typically offers enhanced strength and durability. The interlayer, especially when utilizing SGP, provides increased rigidity, stiffness, and resistance to external forces. This enhances the glass’s ability to withstand impacts, ensuring long-lasting performance and improved safety.

It’s important to note that the specific high specifications and customization options for 6.8mm acoustic laminate glass may vary depending on the manufacturer, supplier, or the particular product offered. Consulting with a glass manufacturer or supplier specializing in acoustic laminated glass will provide you with precise information regarding the high specifications and customization options available for this type of glass based on your specific project requirements.

Additional information

| Weight | 17 kg |

|---|---|

| Glass Type | |

| Glass Thickness | |

| Safety Glass | |

| Min Handling | |

| Max Handling | |

| Unit Price Base Measurement | |

| Unit Price Measurement |

Edge Polishing

BuyGlass.Co pride ourselves on creating a beautiful end product. With edge polishing there are a few things to consider before you purchase & when evaluating the glass you receive.

Depending on the process used, the edge finish can vary slightly between panels. All BuyGlass.Co edge polishing is finished to an exceptional standard and fully QC'd before release.

If you require a uniform finish across all pieces then please contact us after the order is placed.

Otherwise we will process the polishing using whichever process we choose, and although generally this would mean all glass uses the same polishing technique there are certain times when we may use various methods.

Glass Corners

Corners are supplied, as standard, with dubbed corner. If you require unfinished or radius corner please let us know.

Laminated Glass

We use multiple methods for creating laminated glass. CIP, SGP, PVB & EVA are totally different processes which produce very similar results. CIP however, due to the injection process, has a faint area at the perimeter which can be seen upon closer inspection.

** WE GENERALLY USE PVB **

If you would prefer any particular method then you must let us know prior to production or else, at our discretion, we will use any method.