Home

STANDARD SAFETY REPLACEMENT UNITS

A RATED GLASS UNITS Calculator

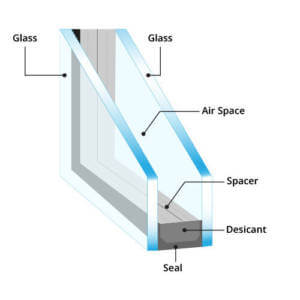

- Double Glazing

Buy Double Glazing Unit | 1st:4mm HP Low E Toughened | 2nd:4mm Clear Toughened | Warm or Alu Spacer | Safety Glass| Energy Efficient Glass

Original price was: £153.36.£100.00Current price is: £100.00. sq m

Shopfront Glazing A Rated

- Double Glazing

Buy DGU | 1st:4mm HP Low E Toughened | 2nd:6.8mm Clear Laminate | Warm or Alu Spacer | Safety Glass| Energy Efficient Glass

Original price was: £184.84.£144.00Current price is: £144.00. sq m

5mm Toughened Glass Calculator

- Bespoke Cut Glass, Toughened Glass

5mm Toughened Glass Calculator | Free Radius, Holes, Polishing, Delivery**

£80.00 - £160.00 / per m2

10mm Toughened Glass Price Calculator

12mm Toughened Glass Calculator

- Bespoke Cut Glass, Toughened Glass

12mm Toughened Glass Calculator | Free Radius, Holes, Polishing, Delivery**

£129.00 - £256.00 / per m2

A+ Rated Slim Double Glazing

C Rated Slim Double Glazing

A Rated Slim Heritage Double Glazing

Fire Rated Glass

7.2mm Pyroguard | EW30

Pyrobel 25 26.6mm | Fire Rated Glass

7mm Pyrodur 30-105 | EW30 | Fire Rated Internal

Bespoke 8mm Toughened Ultra Clear Glass

Bespoke 10mm Toughened Ultra Clear Glass

Bespoke 12mm Toughened Ultra Clear Glass

- Bespoke Cut Glass, Low Iron Toughened Glass, Toughened Glass

12mm Low Iron Toughened Glass Calculator | Free Radius, Holes, Polishing, Delivery**

£215.60 - £431.20 / per m2£184.00 - £368.00 / per m2

11.5mm Laminated Glass Calculator

- Bespoke Cut Glass, Laminate Glass, Toughened Laminated Glass

11.5mm Toughened Laminated Glass Calculator | Free Radius, Holes, Polishing, Delivery**

£252.50 - £505.00 / per m2£202.00 - £404.00 / per m2

15.5mm Laminated Glass Calculator

- Bespoke Cut Glass, Laminate Glass, Toughened Laminated Glass

15.5mm Toughened Laminated Glass Calculator | Free Radius, Holes, Polishing, Delivery**

£330.00 - £660.00 / per m2£264.00 - £528.00 / per m2

17.5mm Laminated Glass Calculator

- Bespoke Cut Glass, Laminate Glass, Toughened Laminated Glass

17.5mm Toughened Laminated Glass Calculator | Free Radius, Holes, Polishing, Delivery**

£292.50 - £585.00 / per m2£234.00 - £468.00 / per m2

Stock - Grey Antique Mirror

- Mirrors, Pre-cut Mirrors, Rectangle, Set Mirrors

6mm – Grey Antique Leaner / Wall Mirror – 1400mm (1.4m) x 600mm (0.6m)

Original price was: £302.40.£254.02Current price is: £254.02.

Stock - Silver Mirror

- Mirrors, Pre-cut Mirrors, Rectangle, Set Mirrors

6mm – Silver Leaner / Wall Mirror – 1600mm (1.6m) x 700mm (0.7m)

Original price was: £105.84.£88.91Current price is: £88.91.

Stock - Bronze Mirror

- Mirrors, Pre-cut Mirrors, Rectangle, Set Mirrors

6mm – Silver bronze Leaner Mirror – 1850mm (1.85m) x 800mm (0.8m)

Original price was: £158.76.£133.36Current price is: £133.36.

A+ Rated Slim GLAZING

C Rated Slimline Double Glazing

A Rated Thin Heritage IGU

WHY BUY GLASS FROM US?

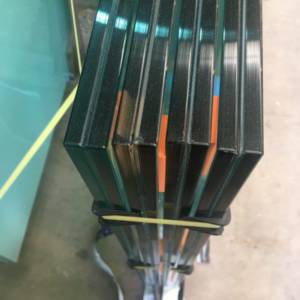

Laminated Glass - BS EN 14449

Toughened Glass - BS EN 12150

Wired Safety Glass

All Security Glass